Masonry equipement – material for models

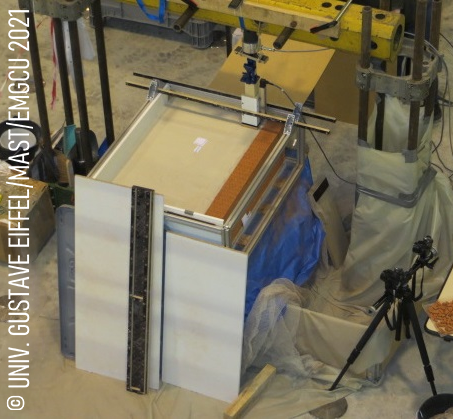

The EMGCU laboratory is equipped with the equipment to carry out uni-axial loading tests on small-scale masonry retaining structures. This test makes it possible to assess the bearing capacity of the embankment-retaining wall complex with respect to a point load. The result obtained is the first step in evaluating the effect of a rolling load on the embankment-wall complex.

Model for loading tests on a road retaining wall

Top view

Front view

The test frame has a glass wall, making it possible to observe the deformations in the backfill and on the section of the wall tested. The frame is associated with a load cell with a nominal capacity of 10 kN. The model is made to 1 / 10th.

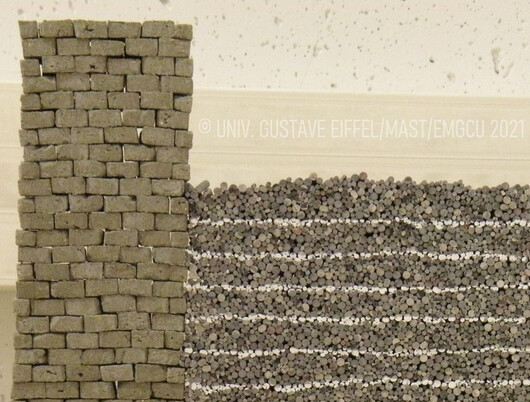

The previously illustrated experimental device allows the realization and study of 3D loads. In a number of cases, a 2D approach is sufficient. For such tests, the EMGCU laboratory is equipped with Schneebeli rollers to form a granular synthetic soil with two-dimensional behavior, used for loading tests on a retaining structure under the assumption of plane deformation.

![[Translate to English:] Rouleaux de Schneebeli](/fileadmin/_processed_/9/2/csm_schneebelli_ca0b9442b0.png)

The Schneebeli material (see image below) consists of duralium rollers of varying diameters (3, 4 and 5 mm in the case considered) with cylindrical or oval sections (flattened cylinder). It reproduces the behavior of a granular soil (sand type) with a friction angle of about 22 °, which has the particularity of only flowing in one direction. This material is therefore perfectly suited to carry out tests studying the behavior of a stressed granular soil, with a minimalist test frame.

The use of models makes it possible to multiply the experiments at a lower cost, which makes it possible to gain a better understanding of the mechanisms involved more quickly. By repeating the same experiments several times, the average values obtained are more statistically representative.

3D Demo

Dry joints wall, vertical facing